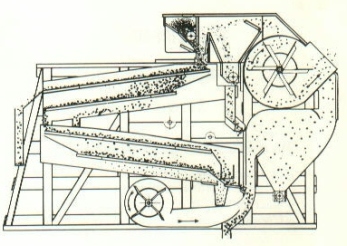

Clipper cleaner model 147BD (seed wheat cleaning)

Clipper cleaner model 147BD

See the VIDEO and PICTURES below!!

This is the Clipper model 147BD seed cleaner. Seed cleaners of this type work similarly like the rear half of the combine harvester after the grain is separated from the stalk or straw only on a much more precise and finer level than a combine moving through the field can. Here is a good link for an explanation on how cleaners like this work. Clipper makes various sizes from table top versions all the way up large commercial units. This unit is an example of a middle of the road "small-medium sized" farm unit. Perfect for our operation. Here is the old way we used to clean seed wheat before planting, better than nothing, but the Clipper is several steps up from the drum type machine seen here.

Cleaning seed (wheat in this case) is an important operation if maximum germination and yields are the goal. Cleaning out broken kernels and other "trash" left over from the harvesting operation helps insure only the biggest and best seeds make it back into the ground for germination. Cleaning out the "trash" also guards against plugging the seed tubes in the seed drill and thus eliminating skipped rows which impacts yields. See my wheat seeding video for more information on this operation. If you have questions ask in the comments below.

This is the Clipper model 147BD seed cleaner. Seed cleaners of this type work similarly like the rear half of the combine harvester after the grain is separated from the stalk or straw only on a much more precise and finer level than a combine moving through the field can. Here is a good link for an explanation on how cleaners like this work. Clipper makes various sizes from table top versions all the way up large commercial units. This unit is an example of a middle of the road "small-medium sized" farm unit. Perfect for our operation. Here is the old way we used to clean seed wheat before planting, better than nothing, but the Clipper is several steps up from the drum type machine seen here.

Cleaning seed (wheat in this case) is an important operation if maximum germination and yields are the goal. Cleaning out broken kernels and other "trash" left over from the harvesting operation helps insure only the biggest and best seeds make it back into the ground for germination. Cleaning out the "trash" also guards against plugging the seed tubes in the seed drill and thus eliminating skipped rows which impacts yields. See my wheat seeding video for more information on this operation. If you have questions ask in the comments below.

Click here for more Farming videos

|

|

|

Here is another type of cleaner, the way we used to clean seed wheat

Koyker rotary screen grain cleaner