The mysterious "electro-tester" The mysterious "electro-tester"

Preservation of Knowledge:

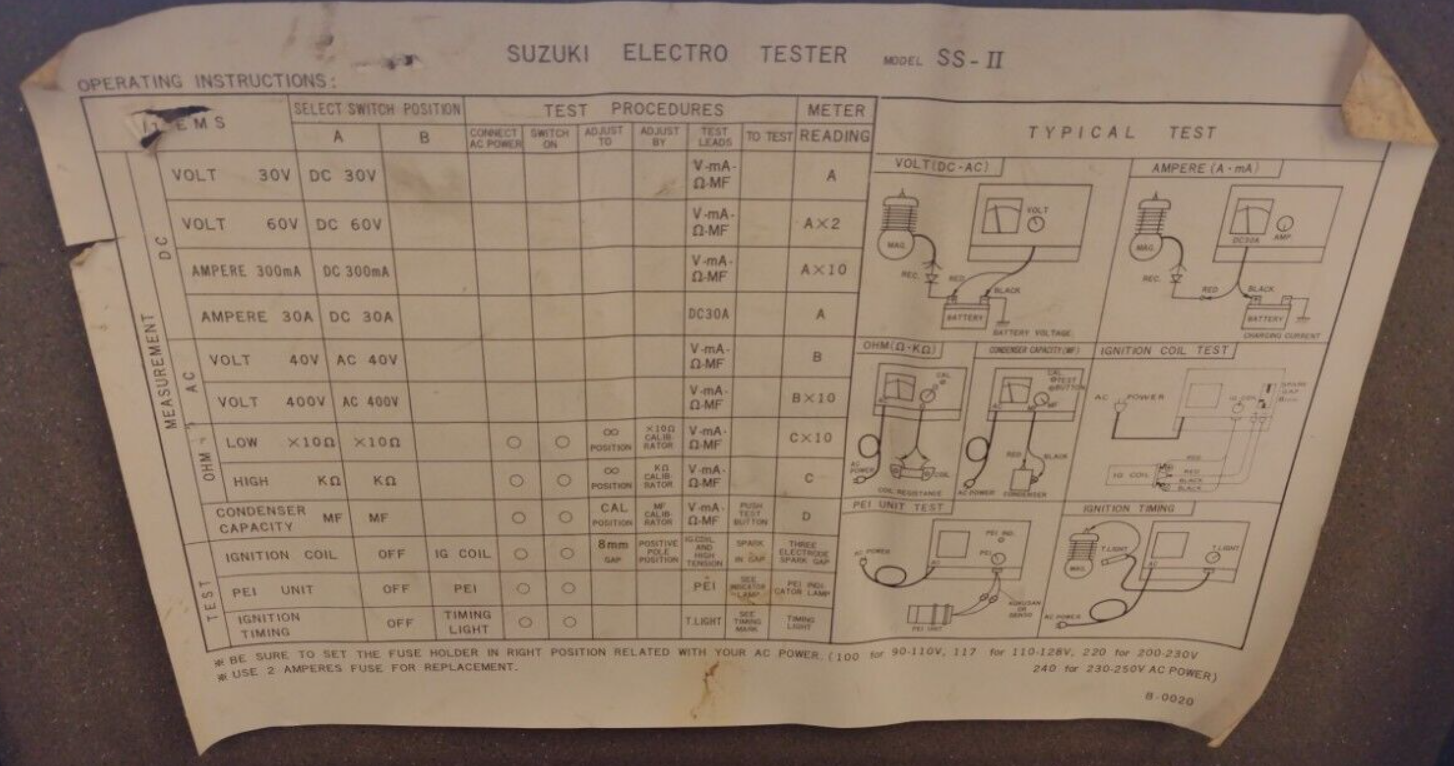

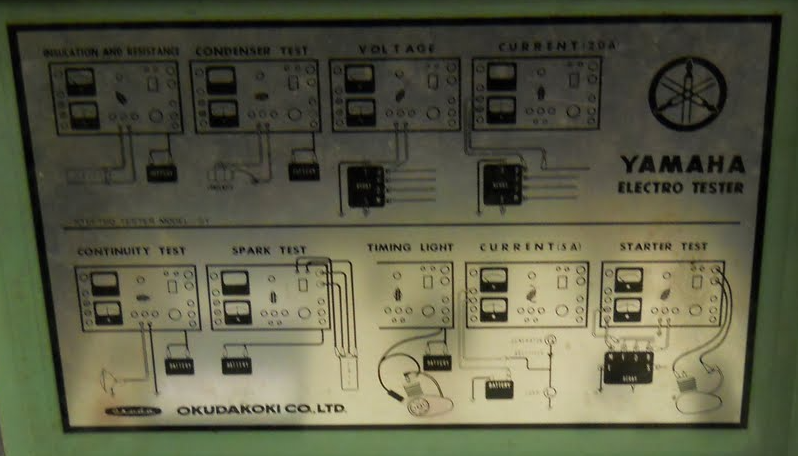

If you are new to working on vintage motorcycles, or even if you are not, chances are you have encountered suspect ignition components. Lets face it these early electronic components, ignition coil, magneto, CDI boxes, ect... are only getting older and older as time marches on. Off to the internet you might say, right? Well sure, that is probably what brought you here, however a lot of responses on the internet will say read your service manual and sure that IS the best starting point. The service manual, especially the one published by the factory, is in fact the bible for your particular bike. That is until you get to sections in that bible that reference certain factory tools for testing, tools that were not (then) and are not (now) readily available. I am talking about certain specialty electronic component testers that were purpose built for factory dealership mechanics to use for servicing these old bikes when they were new. I am talking specifically about a tool colloquially known as Electro-Testers. Multi-function test equipment is nothing new. In fact automotive OEM and aftermarket companies have been making all types of all-in-one type test equipment going all the way back to the early days of the automobile. The problem with these specialty purpose tools is they can fall out-of-date as the years roll on and engine management technology changes and evolves.  Automotive Engine performance tester Automotive Engine performance tester

And here lies the problem with a hobbyist that is trying to keep a motorcycle on the road some 50+ years later. These tools become as hard to find as the knowledge that goes with them. I thought it would be fun to take a look at a few of these specialty tools from a by-gone era and demystify what some of them do.

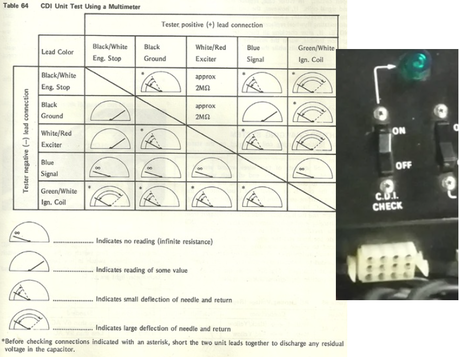

What is an Electro-Tester? Kawasaki CDI unit test outlined in the service manual Kawasaki CDI unit test outlined in the service manual

In the context of vintage motorcycles, an electro tester is a device that combines many diagnostic testers into one conveniently packaged unit. Most of these units encompass all the necessary tester functions related to ignition & sometimes lighting/charging into a box with specific test leads or connectors for each specific component that may need testing. This was done to make quick work of determining if a motorcycle electrical component, for example an ignition coil, was "good" or not.

Why not just use a multi-meter? True, this is a viable option and most service manuals will reference procedures and values for using an off the shelf multi-meter, which is how most at home DIY'ers will have to diagnose specific electrical components. The benefit of these (previously) dealer only tools is that they were compact, contained all the tests in one box and were a, quick plug it in and read the dial, to determine a GO or NO-GO component. The goal was speed, repeatability and reliability. What was really appealing about these devices is some of them could test CDI boxes for certain models. In some Kawasaki manuals it even stated if an Electro-Tester was available (see inset) use the instructions that came with the tester to determine if the CDI unit was good. Sometimes an alternative method with a multi-meter was either not presented or very complex and subjective. Using one of these test boxes would have been a quick task for a mechanic that is on the clock. SO what can some of these all-in-one electro testers do?

Below are some common functions and tests these testers in a box can do, regardless of the manufacturer.

Spark test (Ignition coil test) Spark test (Ignition coil test)

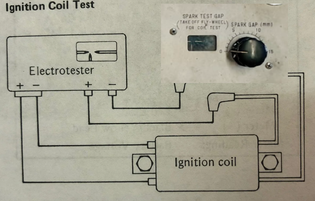

Spark Test Gap/Ignition Coil Test

One of the most useful tests is the ignition coil test. Test leads are attached to the high tension (spark plug) coil. A voltage generated from the tester is used to jump the gap between the two pointed electrodes. A dial is used to vary the gap as the coil is tested as viewed through an observation window. Quality of the spark can be viewed and depending on the maximum gap the spark can jump will determine the quality of the coil. Note: The 3rd electrode is not connected to anything. Its function is to help propagate the initial spark to the opposing electrode when starting the test.  Tachometer & Dwell angle combination gauge Tachometer & Dwell angle combination gauge

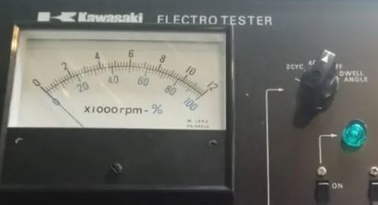

Tachometer/RPM

A tachometer to read engine RPM's was sometimes included on these testers. While not really a test in of itself, the tachometer hooked leads to the spark plug wire and used the ignition firing pulses to then calculate the engines RPM via a sweeping needle indicator. A selector dial to selector between 2 and 4 stroke. The tachometer would have been a useful tool for mechanics working on motocross bikes that didn't have a cable operated tachometer to set things like the idle speed, carburetor tuning at specific RPM's, and testing charging voltage/amps during night time operation. Also this would have been a bit more accurate than a cable operated gauge as those get progressively inaccurate the faster they spin due to frictional losses in the gear train that make them work.  Ignition timing light function Ignition timing light function

Timing Light

Again, not a specific test but a tool to be used in conjunction with other features of the tester. A timing light can help on bikes that have adjustable timing by flashing a light when the spark plug fires. Using the service manual a mechanic can quickly set timing advance on bikes that require it.  Dwell angle adjustment procedure for up to a 4 cylinder engine Dwell angle adjustment procedure for up to a 4 cylinder engine

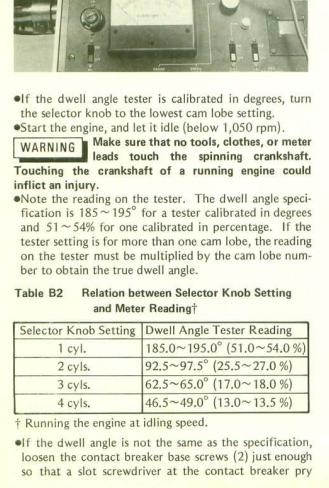

Dwell angle test (see previous tachometer picture)

A test that is specifically for setting accurate timing for contact breaker point type ignitions. The tester can give a readout of the rotational angle (or percentage) of the time the contact breaker points are closing. The service manual will give a value for this and the mechanic can use this mode to slowly open or close the point gap to achieve the correct ignition timing.  Condenser test Condenser test

Condenser capacity test

Related to contact breaker point type ignitions are the capacitors that store up energy that is released through the points and then is stepped up by the high tension (spark plug) coil. Some testers have a mode to test the capacity, displayed as MF (microfarad). When in this mode the capacitor will be charged and its capacity can be measured. The service manual will give a specific value that the capacitor should read. This can make quick work of ruling out a faulty condenser when diagnosing ignition problems.  "CDI Check" consolidates these multi-meter tests into a single opperation "CDI Check" consolidates these multi-meter tests into a single opperation

CDI, PEI, Ignition box test

A simple GO/NO GO test using some internal circuitry to determine a functioning or non functioning ignition box. The actual way the tester determines this is a bit of a mystery at this time. However anecdotal experience is that this test could result in false positives/negatives. More research would need to be done, however back in the day when the electronics were not degraded it was probably fairly accurate at determining faulty CDI boxes on used bikes. Examples of electro-testers from various motorcycle brands

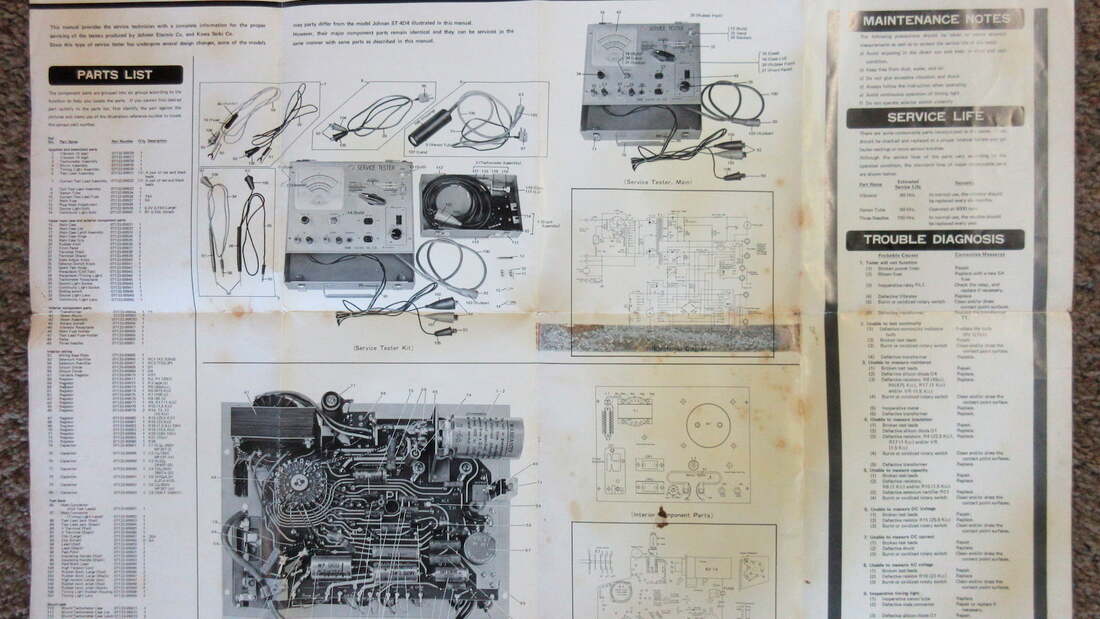

Honda had something similar, but simply called it a SERVICE TESTER, however the functions were pretty much the same as Suzuki and Kawasaki's version in function.

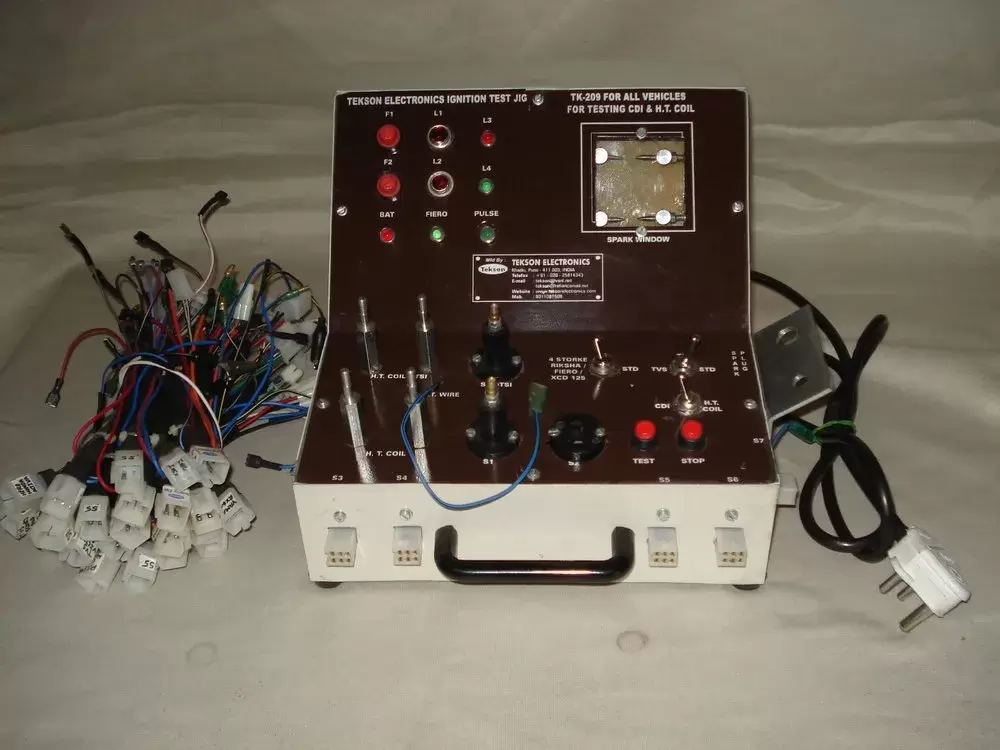

And just in case you thought these tools were just for motorcycles they were pretty common for gasoline automotive applications as well. Here is an example that has bundled connectors for various applications of CDI units that would have come on early cars that had electronic ignition.

Comments

|

Details

AuthorJon "the junk man" helping to promote responsible riding and recreation whether it be at the track or at the trail. Your source for motorcycle how to videos and much more! Archives

February 2023

|

Proudly powered by Weebly

RSS Feed

RSS Feed